Automobile Industry use basalt Fiber Assembled roving

Basalt Assembled roving, which is coated with a silane-based sizing compatible with UR ER VE resins. It is designed for filament winding, pultrusion and weaving applications and is suitable for use in pipes, pressure vessels and profile.

PRODUCT CHARACTERISTICS

- Excellent mechanical property of composite products.

- Excellent chemical corrosion resistance.

- Good processing properties, low fuzz.

- Fast and complete wet-out.

- Multi-resin compatibility.

DATA PARAMETER

|

Item |

101.Q1.13-2400-B |

|||

|

Type of Size |

Silane |

|||

|

Size Code |

Ql |

|||

|

Typical Linear Density (tex) |

1200 |

2400 |

4800 |

9600 |

|

Filament (μm) |

13/16 |

13/16/18 |

13/16/18 |

18 |

TECHNICAL PARAMETERS

|

Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Breaking Strenth(N/Tex) |

|

ISO1889 |

ISO 3344 |

ISO 1887 |

ISO 3341 |

|

±5 |

<0.10 |

0.60±0.15 |

≥0.45(22μm) ≥0.55(16-18μm) ≥0.60(<16μm) |

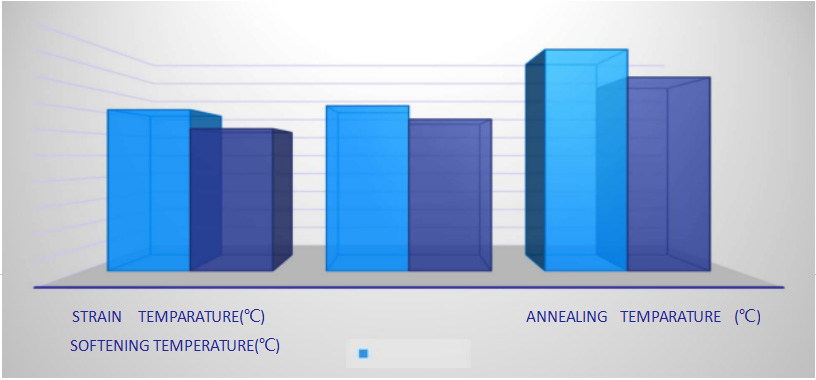

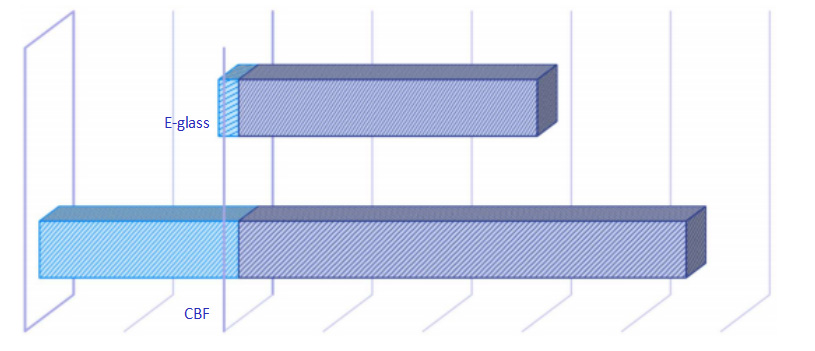

Basalt fiber has an excellent temperature resistance performance because of its special chemical compound. It can bear higher temperature than E-glass, and keeps its mechanical property at low temperatures.

Comparison of High Temperature Resistance Performance

Comparison of Applicable Temperature Range

Application Fields:

Application Fields: Electrical & Electronic Industry, FRP, Automobile Industry, Environmental Protection, Construction, Building Industry, Aerospace, Marine/Boat Building and National Defense Industry.