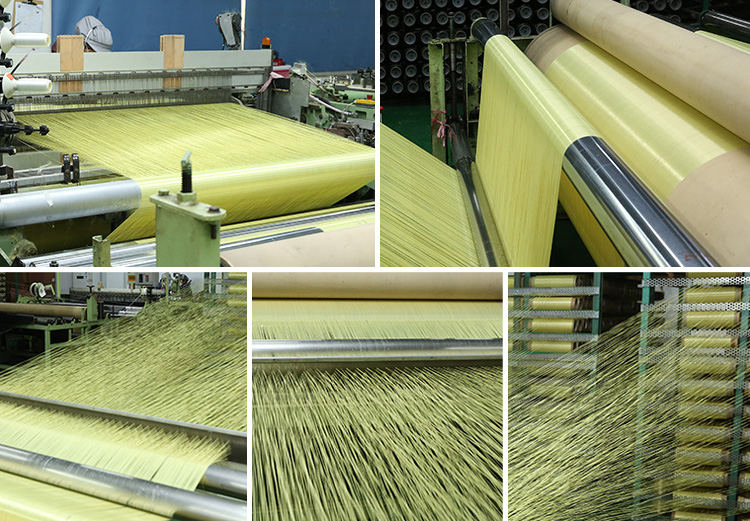

Aramid UD Fabric High Strength High Modulus Unidirectional Fabric

Product Description

Unidirectional aramid fiber fabric refers to a type of fabric made from aramid fibers that are predominantly aligned in a single direction. The unidirectional alignment of aramid fibers provides several advantages. It maximizes the strength and stiffness of the fabric along the fiber direction, offering exceptional tensile strength and load-bearing capabilities. This makes it an excellent choice forapplications where high strength in aspecific direction is required.

Product Parameters

|

Item No.

|

Weave

|

Tensle Strength

|

Tensile Modulus

|

Areal Weight

|

Fabric Thickness

|

|

MPa

|

GPa

|

g/m2

|

mm

|

||

|

BH280

|

UD

|

2200

|

110

|

280

|

0.190

|

|

BH415

|

UD

|

2200

|

110

|

415

|

0.286

|

|

BH623

|

UD

|

2200

|

110

|

623

|

0.430

|

|

BH830

|

UD

|

2200

|

110

|

830

|

0.572

|

Product Characteristics:

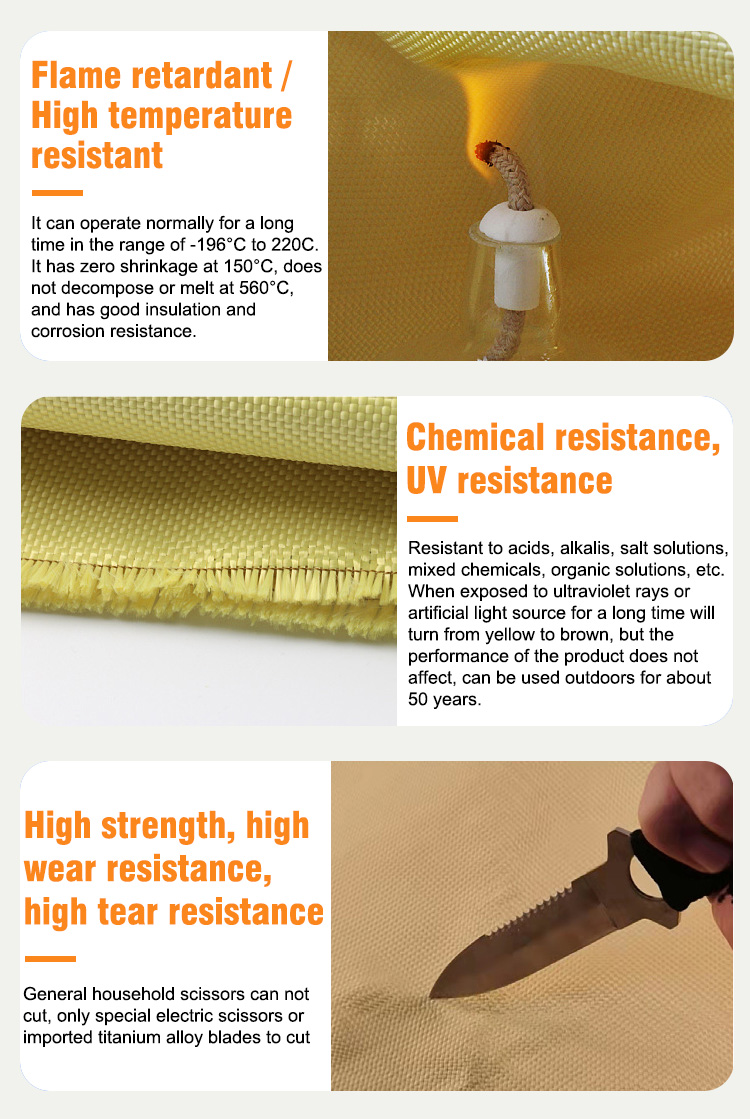

1. High Strength and Stiffness: Aramid fiber unidirectional fabric has excellent tensile strength and stiffness, making it the material of choice for high mechanical stress.

2. High Temperature Resistance: It maintains its properties in high temperature environments, typically withstanding temperatures in excess of 300° C.

3. Chemical Stability: Aramid fiber unidirectional fabrics offer excellent resistance to a wide range of chemicals, including acids, alkalis and organic solvents.

4. Low Coefficient of Expansion: Aramid fiber unidirectional fabrics have a low linear coefficient of thermal expansion at elevated temperatures, allowing them to remain dimensionally stable at elevated temperatures.

5. Electrical insulation properties: It is an excellent electrical insulation material for electronic and electrical applications.

6. Abrasion resistance: Aramid fibers have good abrasion resistance and are suitable for applications that require frequent friction or wear.

Product Applications:

① Protective Gear: Aramid fibers are used in bulletproof vests, helmets, and other protective clothing due to theirexcellent strength and resistance to impact.

② Aerospace Industry: Aramid fibers are utilized in aircraft components, such as lightweight structural panels, due to theirhigh strength-to-weight ratio.

③ Automotive Industry: Aramid fibers are used in the production of high-performance tires, providing improved durability and resistance to wear.

④ Industrial Applications: Aramid fibers find application in ropes, cables, and belts where strength, heat resistance, and resistance to abrasion are crucial.

⑤ Fire Safety: Aramid fibers, are used in firefighter uniforms and protective clothing as they offer excellent flame resistance.

⑥ Sporting Goods: Aramid fibers are used in sporting equipment, such as racing sails and tennis racket strings, for their strength and lightweight nature.