AR Fiberglass Mesh (ZrO2≥16.7%)

Product Description

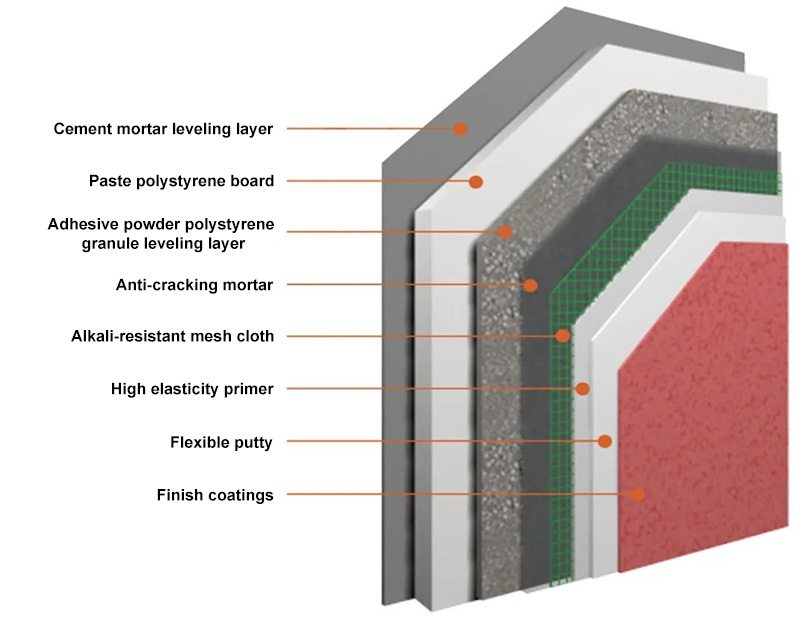

Alkali-resistant fiberglass mesh fabric is a grid-like fabric made of glassy raw materials containing alkali-resistant elements zirconium and titanium after melting, drawing, weaving, and coating. Zirconium oxide (ZrO2≥16.7%) and titanium oxide are introduced into the glass fiber during melting, forming a mixed film of zirconium and titanium ions on the surface, so that the fiber itself can effectively resist the penetrating erosion of Ca(OH) special strong alkaline hydrate in the polymer mortar; and then in the process of forming the original wire by coating alkali-resistant polymer emulsion to form the second protection; after the completion of the weaving, it is then subjected to alkali-resistant and very good compatibility with the cement. After weaving, it is coated with modified acrylic emulsion with excellent compatibility with cement and cured, forming the third layer of organic protective layer with high toughness and strong alkali resistance on the surface of mesh fabric.

Composite alkali-resistant glass fiber mesh cloth can improve the toughness and strength of cement-based products several times to dozens of times, and provide surface anti-cracking performance, and more can be laid through multiple layers to meet the higher-strength products. At present, it has been widely used in the fields of anti-cracking of external wall insulation, beam-column intersection joint treatment, mechanism of cement-based panels, GRC decorative concrete panels, GRC decorative components, flue, road setup, embankment reinforcement, and so on.

Technical Indicators:

| Product Specification | Rupture strength ≥N/5cm | Alkali-resistant retention rate ≥%, JG/T158-2013 standard | ||

| longitudinal | latitudinal | longitudinal | latitudinal | |

| BHARNP20x0-100L(140) | 1000 | 1000 | 91 | 92 |

| BHARNP10x10-60L(125) | 900 | 900 | 91 | 92 |

| BHARNP3x3-100L(125) | 900 | 900 | 91 | 92 |

| BHARNP4x4-100L(160) | 1250 | 1250 | 91 | 92 |

| BHARNP5x5-100L(160) | 1250 | 1250 | 91 | 92 |

| BHARNP5x5-100L(160)H | 1200 | 1200 | 91 | 92 |

| BHARNP4x4-110L(180) | 1500 | 1500 | 91 | 92 |

| BHARNP6x6-100L(300) | 2000 | 2000 | 91 | 92 |

| BHARNP7x7-100L(570) | 3000 | 3000 | 91 | 92 |

| BHARNP8x8-100L(140) | 1000 | 1000 | 91 | 92 |

Product Performance:

Grid positioning good raw materials, raw silk coating, mesh cloth coating triple alkali resistance excellent flexibility, good adhesion, easy to construct, good positioning good soft hardness can be adjusted in real-time according to the customer’s needs and changes in the temperature of the construction environment. High strength, high modulus of elasticity >80.4GPaLow fracture length:2.4%Good compatibility with sanding, high grip.

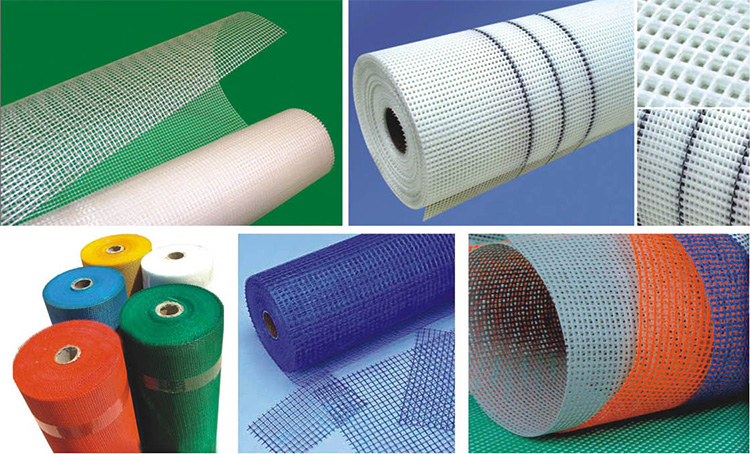

Packing Method:

Every 50m/100m/200m (according to customer’s requirement) a roll of mesh fabric rolled on a paper tube with a radius of 50mm, outer diameter of 18cm/24.5cm/28.5cm, the whole roll is packed in a plastic bag laminated woven bag.

A pallet with dimensions 113 cmx113 cm (total height 113cm) is draped with 36 mesh rolls (the number of mesh rolls varies for different specifications). The whole pallet is packed in hard cartons and wrapping tape, and there is a load-bearing flat plate in the upper part of each pallet that can be stacked in two layers.

The net weight of each pallet is about 290 kg and the gross weight is 335 kg. A 20-foot box holds 20 pallets, and each roll of netting has a self-adhesive label with product reference information. There are two labels on both vertical sides of each pallet with product reference information.

Product Storage:

Keep the original package dry inside and store it upright in an environment with a temperature of 15°C-35°C and relative humidity between 35% and 65%.