3D FRP Sandwich Panel for portable house/mobile barracks/camping houses

Product Description

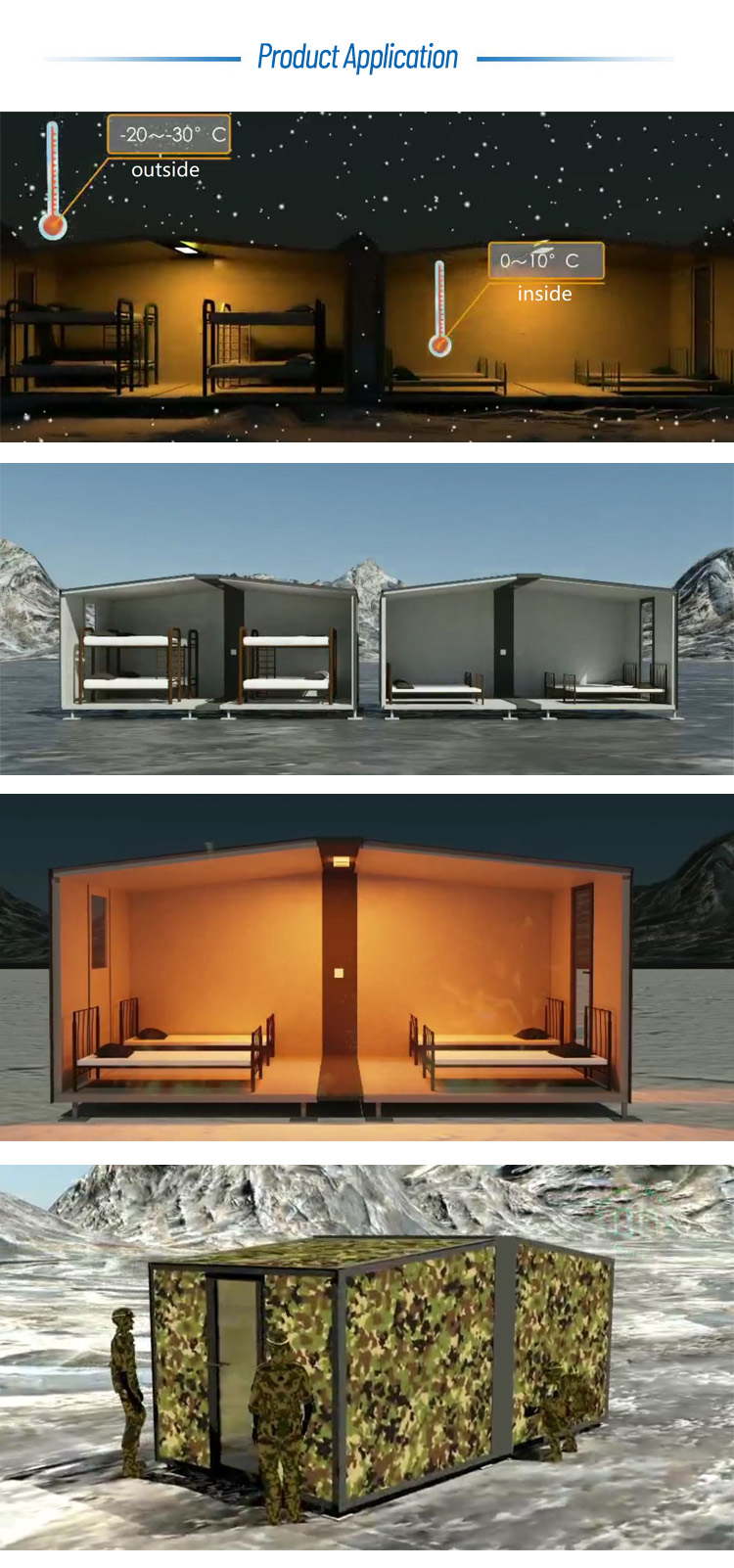

Ultra-efficient templated folding movable barracks, compared with the traditional one-vehicle can only ship a container-type barracks, our modular folding barracks transport volume is greatly reduced, a 40-foot container can be assembled with ten standard rooms, and each standard room can be set up with 4-8 beds, which can satisfy the accommodation needs of 80 people at the same time, and it has the characteristics of ultra-high-efficiency transport and so on.

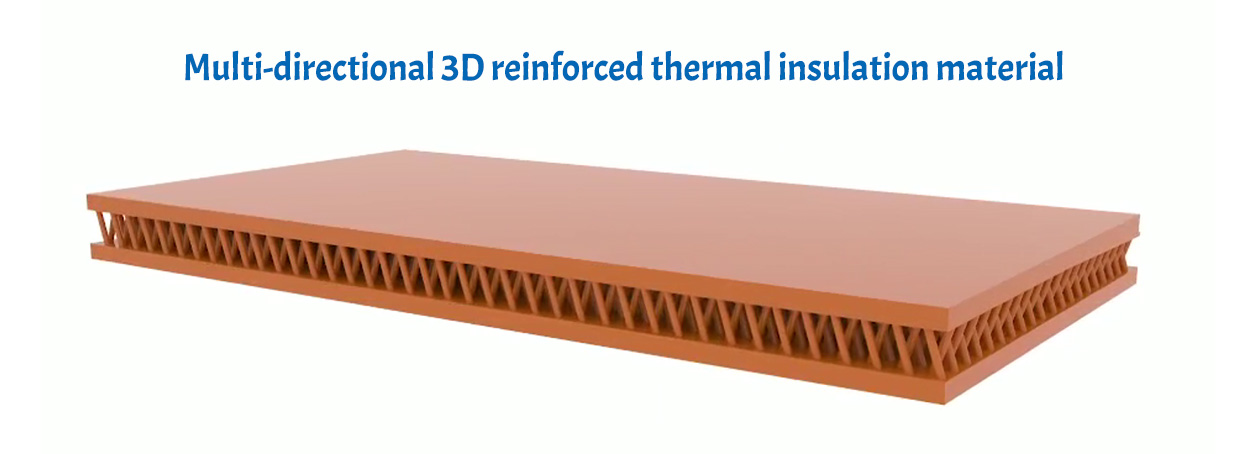

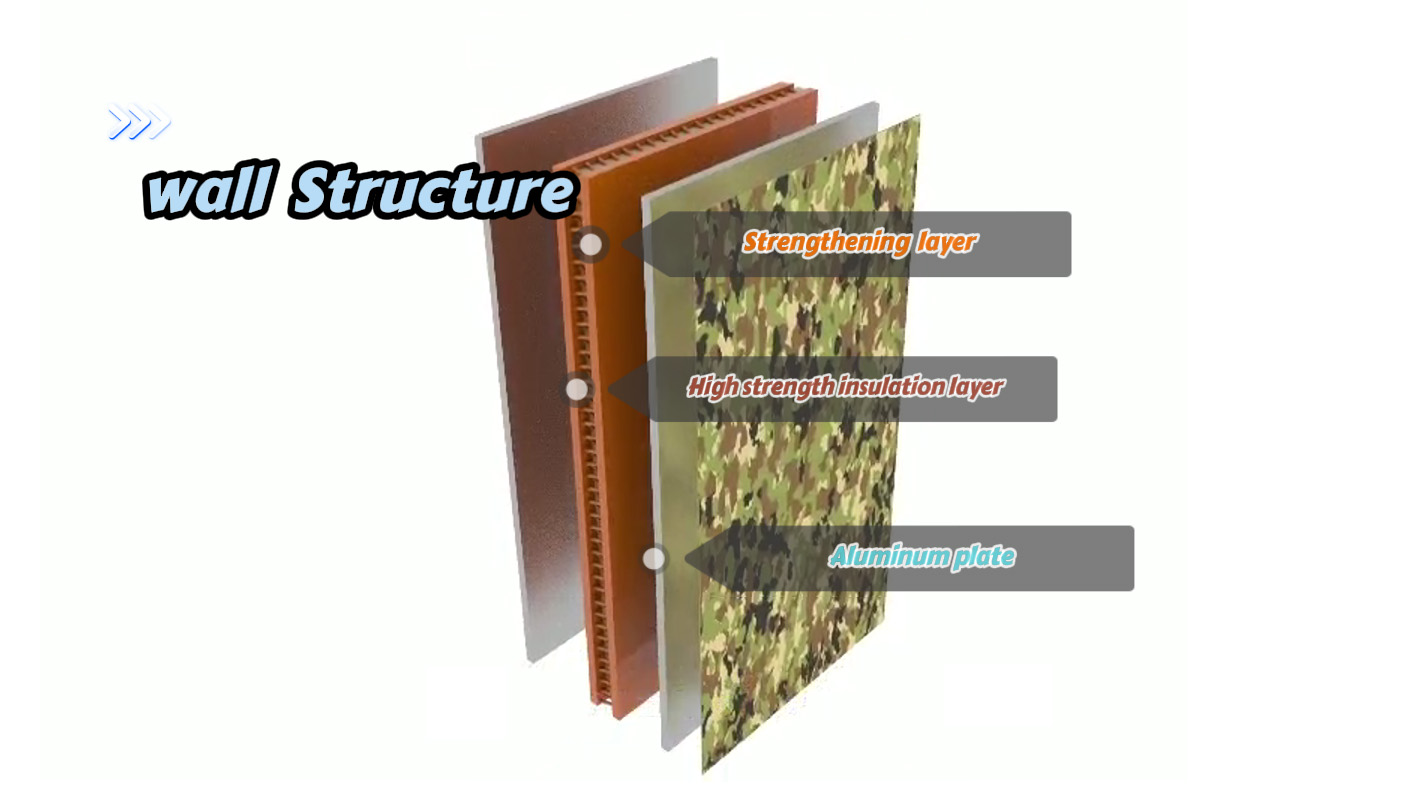

The walls of the folding barracks are manufactured using the sandwich structure principle. It consists of a high-strength insulation layer, a reinforced layer and an aluminium plate, of which the high-strength insulation layer uses a patented multi-directional three-dimensional integrated reinforced insulation material.Compared with the traditional sandwich panel material, the material has ultra-high strength and thermal insulation performance.

For harsh environments, especially in high-cold and high-altitude areas, the material structure has unparalleled superior performance, according to field measurements, in the external environment of minus 20 to 30 degrees Celsius temperature, indoor heating equipment in the use of a single 200 to 500W, the indoor temperature can always be maintained at 0 to 10 degrees above. For the stationing of troops in high-cold areas, can play an important role.In addition, a ballistic energy-absorbing layer can be added to the wall structure, thus upgrading the barracks into a combat barracks with explosion-proof effect. It can effectively resist the impact of stray bullets and fragments caused by explosions outside the house. Maximum protection of the personal safety of soldiers.

3D FRP Sandwich Panel is good material use for make Ultra-efficient templated folding movable barrack.

3D FRP panels are typically made of Fiber Reinforced Plastic (FRP), characterized by lightweight, high strength, corrosion resistance, and good weather resistance. As a result, they find potential applications in portable cabins:

1.Structural Support: 3D FRP panels can be used to manufacture the structural support of portable cabins due to their sufficient strength and lightweight properties, contributing to an overall lightweight structure.

2.Exterior Walls and Roofing Material: 3D FRP panels can serve as covering materials for exterior walls and roofs, providing insulation, waterproofing, and decorative features.

3.Thermal and Acoustic Insulation: FRP materials typically exhibit good thermal and acoustic insulation properties, enhancing comfort in portable cabins.

4.Corrosion Resistance: Due to the excellent corrosion resistance of 3D FRP panels, they are suitable for various environments, including coastal areas or around chemical plants, proving valuable in specific applications.

5.Ease of Processing: FRP materials are relatively easy to process and manufacture, allowing for customization of shapes according to design requirements, suitable for various styles and specifications of portable cabins.