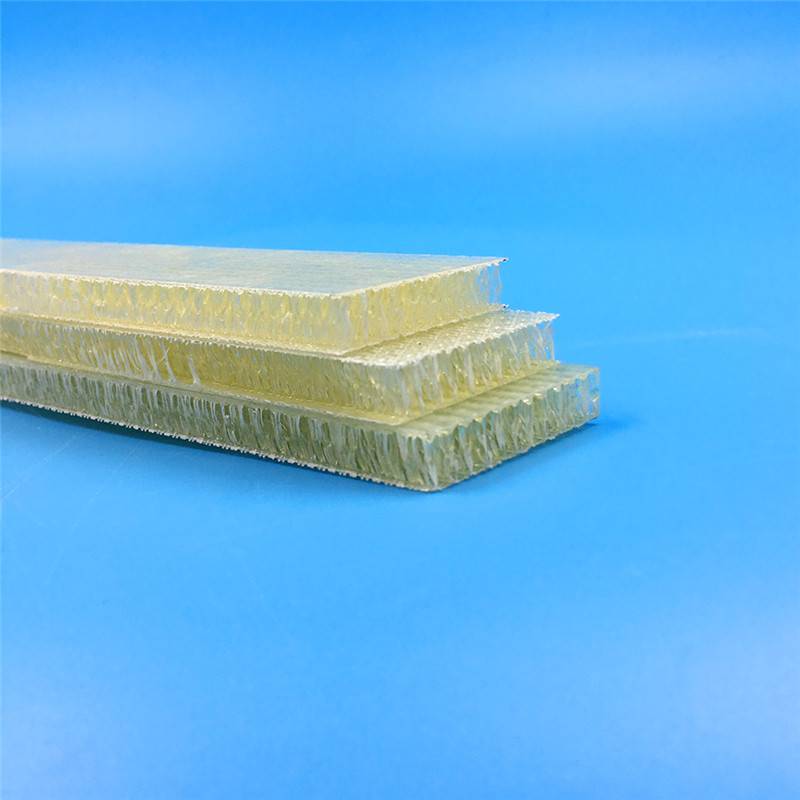

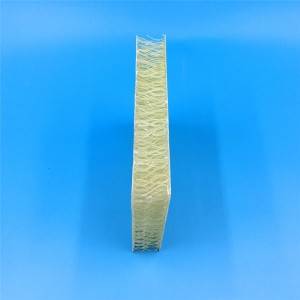

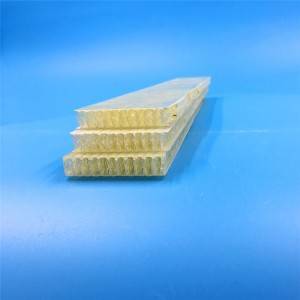

3D FRP Panel with resin

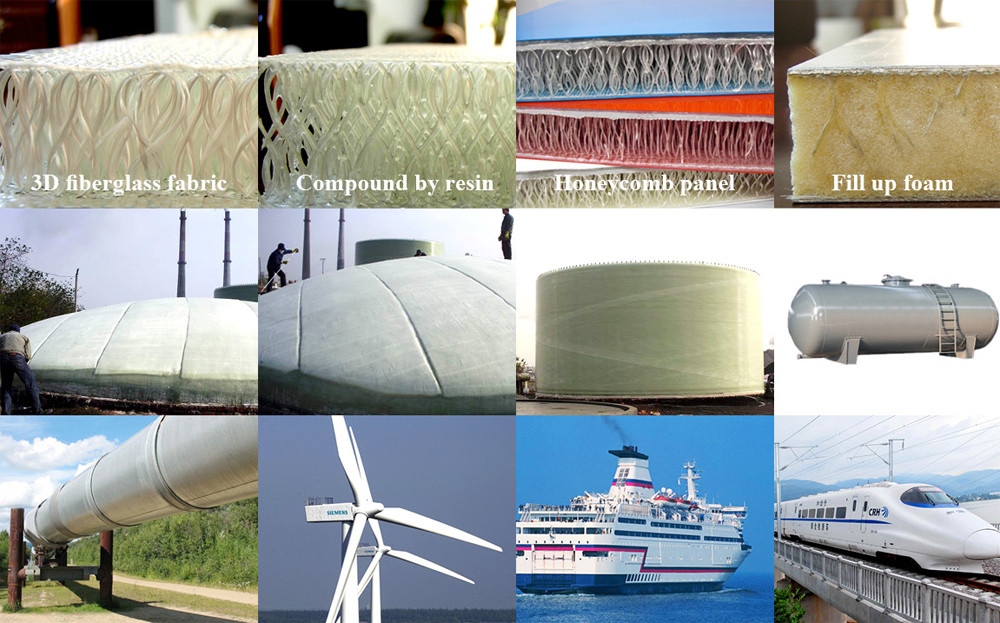

The 3-D Fiberglass Woven fabric can composite with different resins(polyester,Epoxy,Phenolic and etc), then the final product is 3D composite panel.

Advantage

1. light weight bur high strength

2. Great resistance against delamination

3. High design – versatility

4. Space between both deck layers can be multifunctional(Embedded with sensors and wires or infused with foam)

5. Simple and effective lamination process

6. Heat insulation and sound insulation, Fireproof, Wave transmittable

Application

Specification

| Pillar Height | mm | 4.0 | 6.0 | 8.0 | 10.0 | 12.0 | 15.0 | 20.0 | |

| Warp Density | root/10cm | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Weft Density | root/10cm | 96 | 96 | 96 | 96 | 96 | 96 | 96 | |

| Face Density | 3-D spacer fabrics | kg/m2 | 0.96 | 1.01 | 1.12 | 1.24 | 1.37 | 1.52 | 1.72 |

| 3-D spacer fabrics and sandwich construction | kg/m2 | 1.88 | 2.05 | 2.18 | 2.45 | 2.64 | 2.85 | 3.16 | |

| Flatwise Tensile Strength | MPa | 7.5 | 7.0 | 5.1 | 4.0 | 3.2 | 2.1 | 0.9 | |

| Flatwise Compressive Strength | MPa | 8.2 | 7.3 | 3.8 | 3.3 | 2.5 | 2.0 | 1.2 | |

| Flatwise Compressive modulus | MPa | 27.4 | 41.1 | 32.5 | 43.4 | 35.1 | 30.1 | 26.3 | |

| Shear Strength | Warp | MPa | 2.9 | 2.5 | 1.3 | 0.9 | 0.8 | 0.6 | 0.3 |

| Weft | MPa | 6.0 | 4.1 | 2.3 | 1.5 | 1.3 | 1.1 | 0.9 | |

| Shear modulus | Warp | MPa | 7.2 | 6.9 | 5.4 | 4.3 | 2.6 | 2.1 | 1.8 |

| Weft | MPa | 9.0 | 8.7 | 8.5 | 7.8 | 4.7 | 4.2 | 3.1 | |

| Bending Rigidity | Warp | N.m2 | 1.1 | 1.9 | 3.3 | 9.5 | 13.5 | 21.3 | 32.0 |

| Weft | N.m2 | 2.8 | 4.9 | 8.1 | 14.2 | 18.2 | 26.1 | 55.8 | |

Note: The above performance index for information purposes only, based on the user’s performance requirements, 3D spacer fabric reinforcement structure can be designed.

Write your message here and send it to us