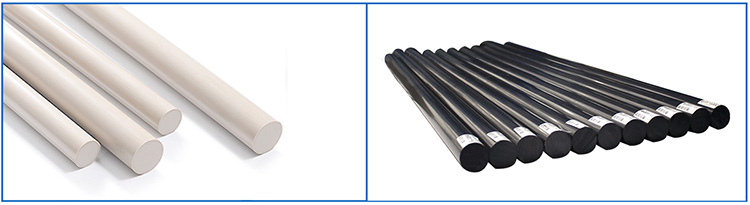

35 mm Diameter PEEK Rods of Continuous Extrusion

Product Description

PEEK rods, Chinese name for polyether ether ketone rods, is a semi-finished profile using PEEK raw material extrusion molding, with high temperature resistance, high abrasion resistance, high tensile strength, good flame retardant properties.

PEEK Sheet Introduction

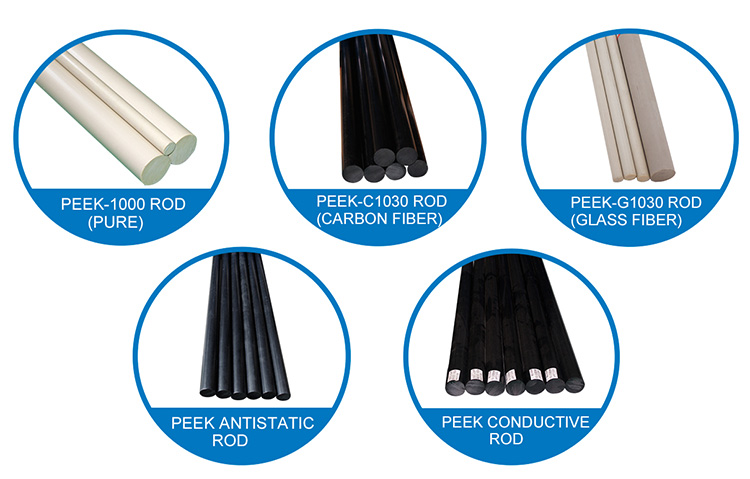

|

Materials |

Name |

Feature |

Color |

|

PEEK |

PEEK-1000 rod |

Pure |

Natural |

|

PEEK-CF1030 rod |

Add 30% carbon fiber |

Black |

|

|

PEEK-GF1030 rod |

Add 30% fiberglass |

Natural |

|

|

PEEK Anti static rod |

Ant static |

Black |

|

|

PEEK conductive rod |

electrically conductive |

Black |

Product Specification

|

Dimensions(MM) |

Reference Weight (KG/M) |

Dimensions (MM) |

Reference Weight (KG/M) |

Dimensions(MM) |

Reference Weight (KG/M) |

|

Φ4×1000 |

0.02 |

Φ28×1000 |

0.9 |

Φ90×1000 |

8.93 |

|

Φ5×1000 |

0.03 |

Φ30×1000 |

1.0 |

Φ100×1000 |

11.445 |

|

Φ6×1000 |

0.045 |

Φ35×1000 |

1.4 |

Φ110×1000 |

13.36 |

|

Φ7×1000 |

0.07 |

Φ40×1000 |

1.73 |

Φ120×1000 |

15.49 |

|

Φ8×1000 |

0.08 |

Φ45×1000 |

2.18 |

Φ130×1000 |

18.44 |

|

Φ10×1000 |

0.125 |

Φ50×1000 |

2.72 |

Φ140×1000 |

21.39 |

|

Φ12×1000 |

0.17 |

Φ55×1000 |

3.27 |

Φ150×1000 |

24.95 |

|

Φ15×1000 |

0.24 |

Φ60×1000 |

3.7 |

Φ160×1000 |

27.96 |

|

Φ16×1000 |

0.29 |

Φ65×1000 |

4.64 |

Φ170×1000 |

31.51 |

|

Φ18×1000 |

0.37 |

Φ70×1000 |

5.32 |

Φ180×1000 |

35.28 |

|

Φ20×1000 |

0.46 |

Φ75×1000 |

6.23 |

Φ190×1000 |

39.26 |

|

Φ22×1000 |

0.58 |

Φ80×1000 |

7.2 |

Φ200×1000 |

43.46 |

|

Φ25×1000 |

0.72 |

Φ80×1000 |

7.88 |

Φ220×1000 |

52.49 |

Note:This table is the specifications and weight of PEEK-1000 sheet (pure), PEEK-CF1030 sheet (carbon fiber), PEEK-GF1030 sheet (fiberglass), PEEK anti static sheet, PEEK conductive sheet can be produced in the specifications of the above table. The actual weight may be a little different, please refer to the actual weighing.

PEEK rods have the four main characteristics:

1. PEEK plastic raw material injection molding shrinkage is small, which is very good for controlling the size tolerance range of PEEK injection molded parts, so that the dimensional accuracy of PEEK parts than general-purpose plastics is much higher;.

2. Small coefficient of thermal expansion, with the change in temperature (can be caused by changes in ambient temperature or frictional heating during operation), the size of the part changes are very small.

3. Good dimensional stability, dimensional stability of plastics refers to the engineering plastic products in use or storage process of dimensional stability of performance, because the activation energy of polymer molecules to increase the chain segments have a certain degree of curling leads to; 4.

4.PEEK outstanding heat hydrolysis resistance, in the high temperature and high humidity environment, water absorption is very low, will not appear similar to nylon and other general-purpose plastics due to water absorption and make the size of the situation of significant changes.

Uses of PEEK rods

PEEK rods can be used to process various specifications of PEEK parts, which can be used to manufacture high-demanding mechanical parts, such as gears, bearings, valve seats, seals, pump wear rings, gaskets and so on.