2021 wholesale price Flush Fiberglass Door - 3D Fiberglass Woven Fabric – Beihai Fiberglass

2021 wholesale price Flush Fiberglass Door - 3D Fiberglass Woven Fabric – Beihai Fiberglass Detail:

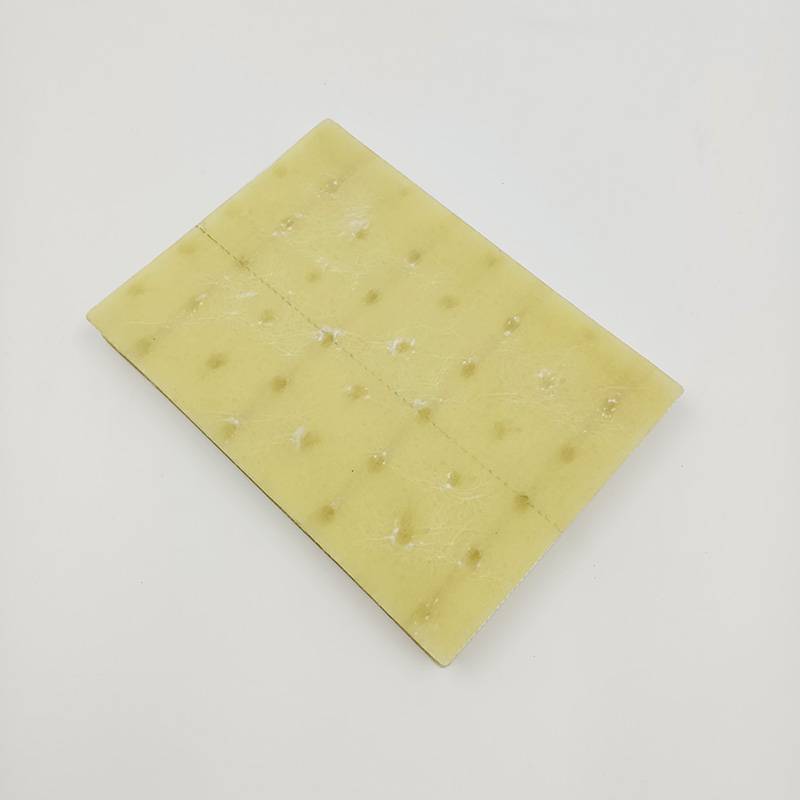

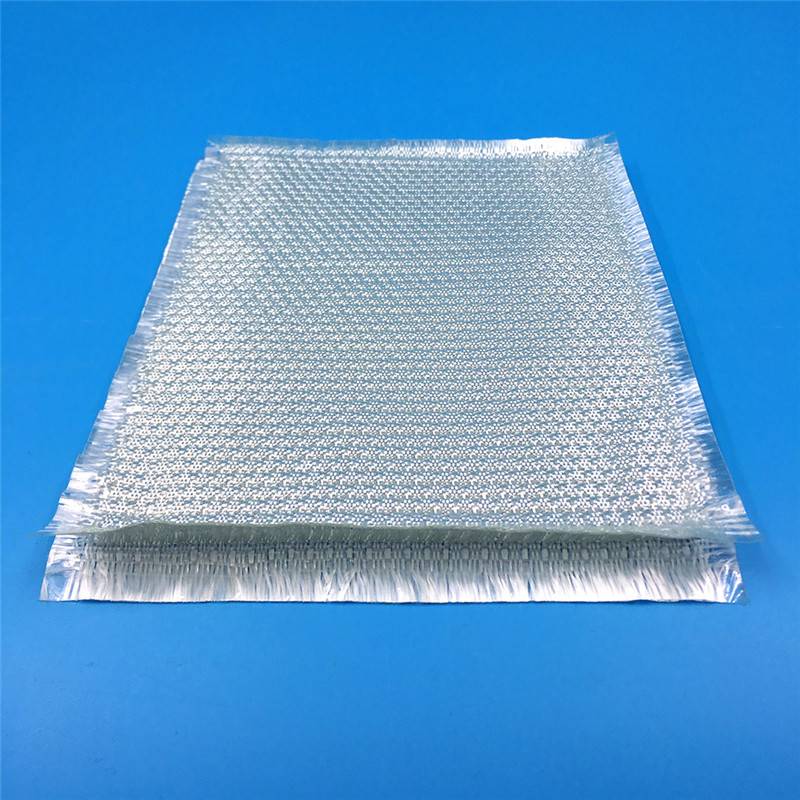

The 3-D spacer fabric consists of two bi-directional woven fabric surfaces, which are mechanically connected with vertical woven piles. And two S-shaped piles combine to form a pillar, 8-shaped in the warp direction and 1-shaped in the weft direction.

Product Characteristics

The 3-D spacer fabric can be made of glass fiber, carbon fiber or basalt fiber. Also their hybrid fabrics can be produced.

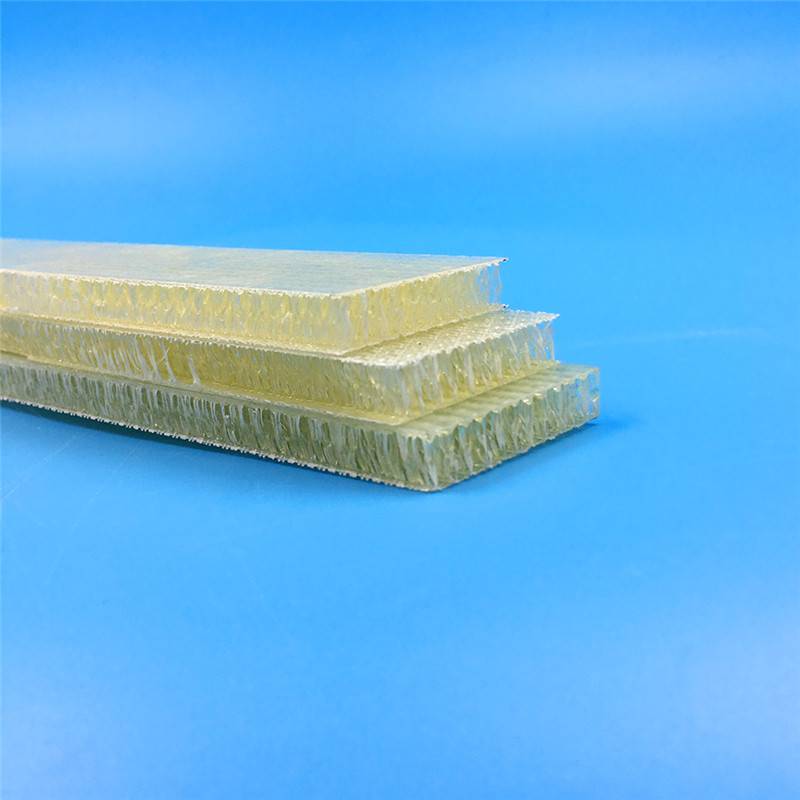

The range of the pillar height:3-50 mm, the range of the width:≤3000 mm.

The designs of structure parameters including the areal density, the height and distribution density of the pillars are flexible.

The 3-D spacer fabric composites can provide high skin-core debonding resistance and impact resistance and impact resistance, light weight. high stiffness, excellent thermal insulation, acoustic damping, and so on.

Application

3D Fiberglass Woven Fabric Specifications

|

Area Weight (g/m2) |

Core Thickness (mm) |

Density of Warp (ends/cm) |

Density of Weft (ends/cm) |

Tensile strength Warp(n/50mm) |

Tensile strength Weft(n/50mm) |

|

740 |

2 |

18 |

12 |

4500 |

7600 |

|

800 |

4 |

18 |

10 |

4800 |

8400 |

|

900 |

6 |

15 |

10 |

5500 |

9400 |

|

1050 |

8 |

15 |

8 |

6000 |

10000 |

|

1480 |

10 |

15 |

8 |

6800 |

12000 |

|

1550 |

12 |

15 |

7 |

7200 |

12000 |

|

1650 |

15 |

12 |

6 |

7200 |

13000 |

|

1800 |

18 |

12 |

5 |

7400 |

13000 |

|

2000 |

20 |

9 |

4 |

7800 |

14000 |

|

2200 |

25 |

9 |

4 |

8200 |

15000 |

|

2350 |

30 |

9 |

4 |

8300 |

16000 |

FAQ of Beihai 3D fiberglass 3D woven fabric

1)How can I add more layers and other materials to the Beihai3D fabric?

You can apply other materials (CSM, roving, foam etc) wet on wet on the Beihai 3D fabric. Up to 3 mm glass can be rolled on wet Beihai 3D before the end of the finished-time and the full spring-back force will be guaranteed. After the gel-time layers of superior thickness can be laminated.

2)How to apply decorative laminates (e.g. HPL Prints) on the Beihai 3D fabrics?

Decorative laminates can be used on the mould-side and the fabric is laminated directly on top of the laminate or the decorative laminates can be rolled over the wet Beihai 3D fabric.

3)How to make an angle or curve with Beihai 3D?

One advantage of Beihai 3D is that it is fully shapeable and drapeable. Simply fold the fabric in the desired angle or curve in the mold and roll well.

4)How can I color the Beihai 3D laminate?

By coloring the resin (adding a pigment to it)

5)How can I obtain smooth surface on the Beihai 3D laminates like the smooth surface on your samples?

The smooth surface of the samples requires a smooth waxed mold, i.e. glass or melamine. In order to obtain a smooth surface on both sides, you can apply a second waxed mold (clamp mold) onto the wet Beihai 3D, taken into account the thickness of the fabric.

6)How can I be sure that the Beihai 3D fabric is completely impregnated?

You can easily tell by the level of transparency if the Beihai 3D has been wetted out properly. Avoid oversaturated areas (inclusions) by simply rolling the excess resin to the edge- and out of the fabric. This will leave the right amount of resin remaining in the fabric.

7)How can I avoid a print-through on the gelcoat of Beihai 3D?

• For most applications, a simple veil or layer of CSM is sufficient.

• For more critical visual applications, you can use a print-blocking barrier coat.

• Another way is to let the outer skin cure before adding Beihai 3D.

8)How can I ensure the translucency of the Beihai 3D laminate?

The translucency is a result of the color of the resin, contact your resin supplier.

9)What is the reason of the rising (spring back) capacity of the Beihai 3D fabric?

Beihai 3D Glass Fabrics are cleverly designed around the natural qualities of glass. Glass can be ‘bent’ but cannot be ‘creased’. Imagine all those springs throughout the laminate pushing the decklayers apart, the resin stimulates this action (also called capillarity).

10)The Beihai 3D fabric does not cure well enough, what should I do?

Two possible solutions

1) When working with resins containing styrene, the entrapment of volatile styrene with the impregnated Beihai 3D could cause cure inhibition. A low(er) styrene emission (LSE) type of resin or alternatively the addition of a styrene emission reducer (e.g. Byk S-740 for polyester and Byk S-750) to the resin is recommended.

2) To compensate the low masses of resin and therewith decreased curing temperature in the vertical pile threads, a highly reactive cure is recommended. This can be achieved with an increased catalyst level and with an increased level (preferably catalyst) compensated with an inhibitor to set the gel time.

11)How can I avoid damages in the surface quality of Beihai 3D (wrinkles and folds in the decklayers)?

Storage is important for the ensurance of the quality: stock the rolls horizontally in a dry environment at normal temperatures unroll the fabric evenly and do not fold the fabric.

• Folds: you can remove folds by easily sliding the roller away from the fold when rolling next to it

• Wrinkles: rolling gently over the wrinkle will simply cause it to disappear

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of 2021 wholesale price Flush Fiberglass Door - 3D Fiberglass Woven Fabric – Beihai Fiberglass , The product will supply to all over the world, such as: Iran, Greenland, Florence, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.