2021 China New Design 3d Woven Glass Fiber Fabric - 3D FRP Sandwich Panel – Beihai Fiberglass

2021 China New Design 3d Woven Glass Fiber Fabric - 3D FRP Sandwich Panel – Beihai Fiberglass Detail:

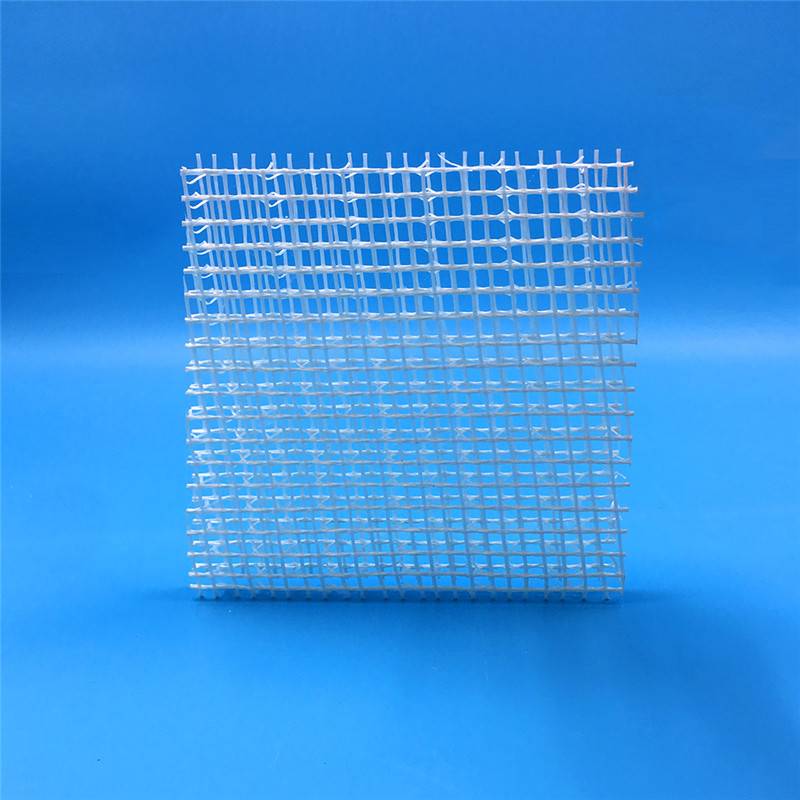

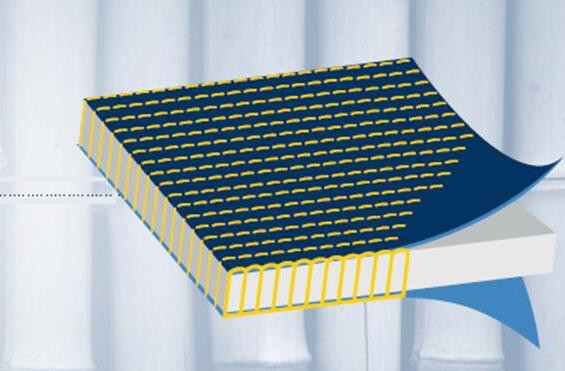

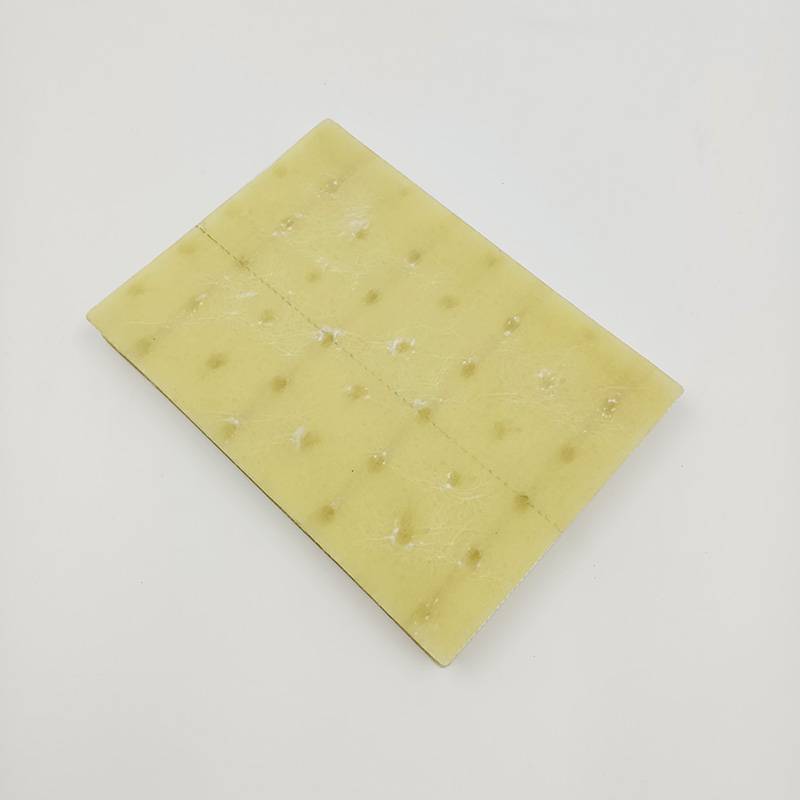

3D FRP stiched foam sandwich panel is new process.New process can produce high strength and density of homogeneous composite panel. Sew highdensity PU plate into the special 3 d fabric, through the RTM (vacuum moldig process).

Advantage

●Fully Fashioned.

●Panel face is very beautiful,

●High strength.

●One-time finishing, slove the problem of traditional sandwich panel foaming.

Structure chart

If it is molded in ordinary 3D cloth and then filled with PU foam, the foam will not be uniform, and the density will not be consistent. The strength of the panel will be very low.

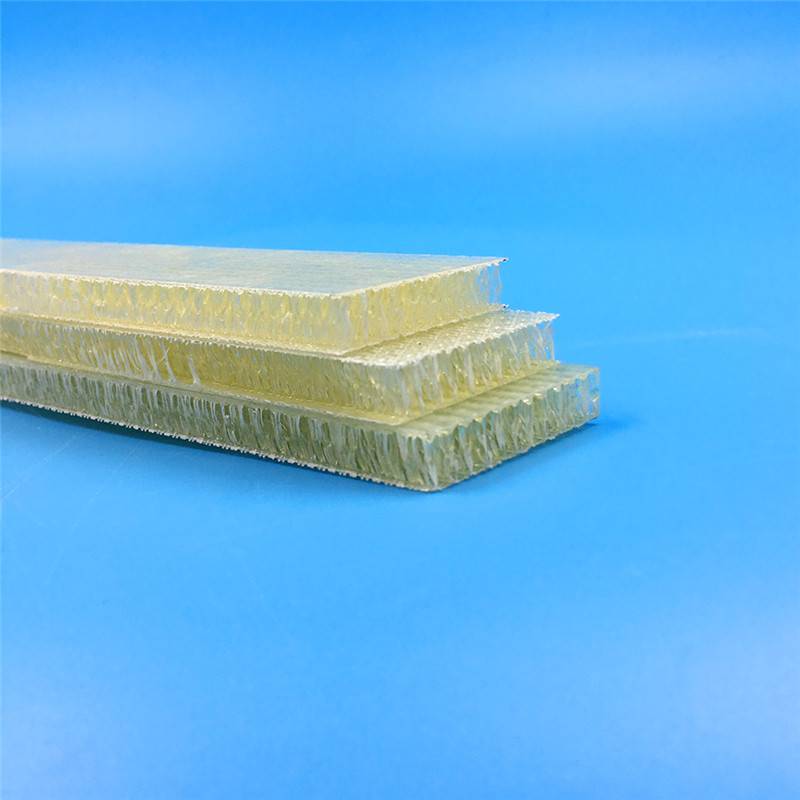

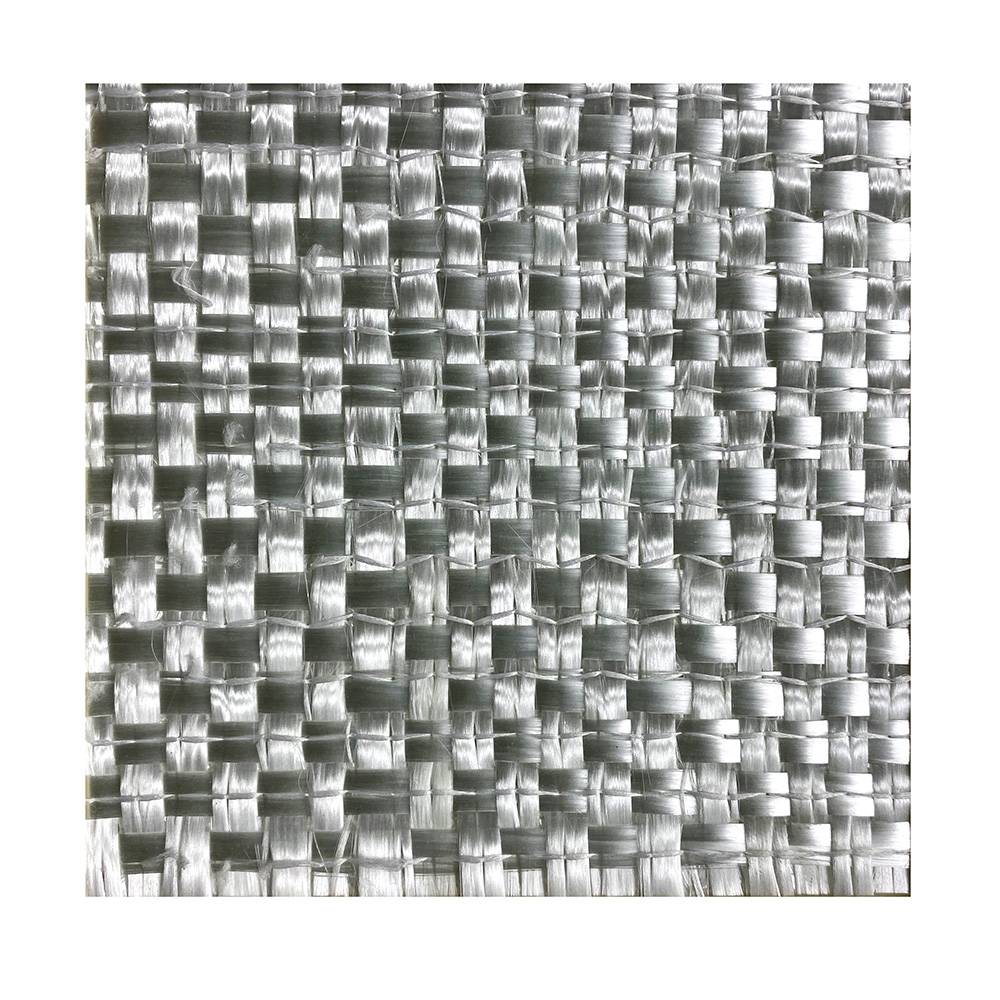

The largest width is 1500mm, you can choose the different foam, such as PU,PVC and so on. The PVC foam strength is higher than PU, the price is also higher. The PU foam thinnest is 5mm,the PVC foam thinnest is 3mm.The normal size is 1200x2400mm, for the normal panel choose the PU foam(density 40kg/m3) +two sides combo mat or woven roving, the total thickness is 20mm.

Application

Benefits of RTM

| The benefits of RTM | What does it bring you? |

| Product surface will be fully defined during pressing | Low finishing costs and beautiful quality |

| Large mould freedom and high fibre-volume(up to 60%) | Ultimate mechanic properties |

| Constant Reproducible | Low dropout rate and suited for advanced applications |

| Continuous innovative industrialisation | Cost savings, higher tool capacity |

| Closed mould technique | Barely any emissions and operator friendly |

Product detail pictures:

Related Product Guide:

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for 2021 China New Design 3d Woven Glass Fiber Fabric - 3D FRP Sandwich Panel – Beihai Fiberglass , The product will supply to all over the world, such as: Bogota, European, Germany, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.